WHERE IT ALL BEGAN

NEW HARTFORD, CONNECTICUT

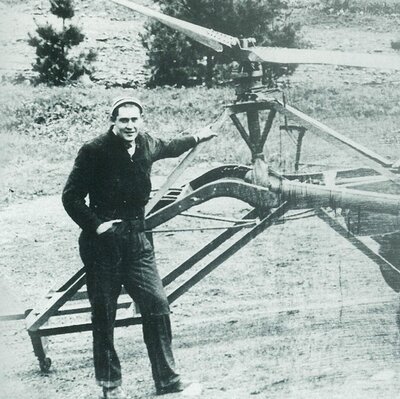

Ovation was a subsidiary of the Kaman Corporation, an aerospace company employing more than 2,700 employees, with 25% of them being scientists, engineers and technicians. Charles Kaman, the president and a guitar enthusiast, decided that his company could apply its technology to the age-old art of guitar making.

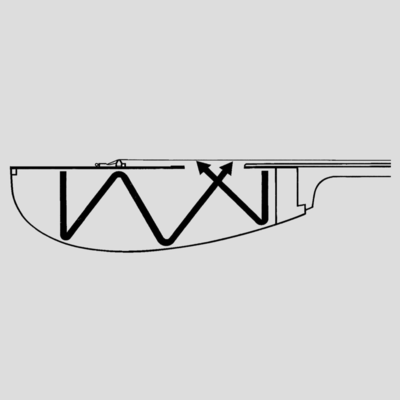

In 1966, after 18 months of testing and research, the Kaman engineers concluded that the most efficient shape for a guitar back is semi-parabolic. The sound such a shape produced from any given energy input was, they found, measurably richer, fuller, deeper and more constant from top to bottom of the scale.

Having made this determination as to shape, the engineers next undertook to find a better material. Since the early Crusades, flat-backed, straight-sided guitars have been made of wood. But the Kaman people felt that even the best woods had serious limitations.

Among the limitations:

Wood is difficult if not impossible to contour to the new round shape. It would require the use of internal bracing and reinforcing members, and, as in conventional guitars, these members would act as baffles, substantially dampening and absorbing the sounds, and setting up non-repetitive vibration patterns which the human ear hears as noise. A guitar top must vibrate to help amplify tone. To vibrate properly, it must be extremely thin and thin wood is, of course, fragile. Sound, like light, reflects best from a smooth surface, and wood is porous. The cellular structure of wood and the natural oils in it vary considerably, not only from one guitar to another, but within a single instrument. The varying densities thus created make it extremely difficult to achieve consistent vibrating characteristics.

Finally they found one, the molecular structure of which actually could be “tuned” (chemically and by heat treating) to a precise degree of resonance.

Lyrachord can be precision-molded to any shape, entirely free of bracing or reinforcing.

It can be made as thin as desired for vibration purposes and yet remain practically indestructible. It can’t warp, chip, crack, check or split

It has a smooth, highly sound-reflectant surface – far superior to wood

Its inorganic composition is non-variable, assuring uniform vibrating characteristics not only from one instrument to another, but from tone to tone within a single instrument

It is indeed an ideal substance – a major contribution in the development of the most scientifically advanced guitar in 400 years

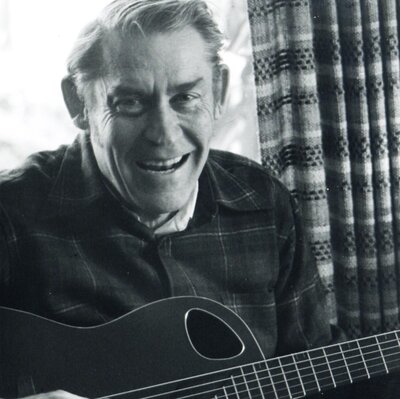

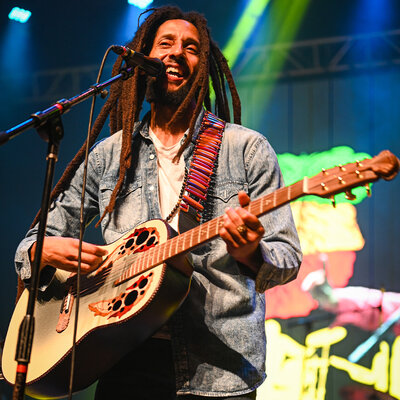

Lyrachord is still the material we use today, to create these truly remarkable instruments. Listen for yourself. Hear the rounder, fuller, totally unique sound of the Ovation Roundback. Let your own ear confirm the difference that aerospace technology has created. We think you’ll agree, you’ve never heard it so good!